Shallow Air Flotation primarily utilizes three key principles: the Air Flotation Principle, the Shallow Tank Principle, and the Zero Velocity Principle.

•Air Flotation Principle: A large number of micro-bubbles are introduced into the wastewater to form a three-phase mixture of water, air, and the substance to be removed. Under the combined action of various forces such as interfacial tension, bubble buoyancy, and hydrostatic pressure difference, the micro-bubbles adhere to the tiny suspended particles to be removed. The density of the resulting agglomerate becomes less than that of water, causing it to float to the surface. This allows for the separation and removal of pollutants from the water.

•Shallow Tank Principle: The shallow air flotation unit integrates flocculation, air flotation, scum removal, and sludge scraping into one unit. The hydraulic retention time is 3-5 minutes. It features forced water distribution and static separation. The adhesion of micro-bubbles to flocs occurs throughout the entire flotation separation process, including the contact zone. Scum is removed instantaneously with minimal disturbance to the water body, resulting in low effluent suspended solids (SS), high scum solids content, SS removal rates up to 99.5% or higher, COD removal rates up to 90% or higher, and color removal rates up to 95% or higher.

•Zero Velocity Principle: The raw water to be treated is pumped to the central inlet pipe by a lift pump. Simultaneously, dissolved air water and chemicals are injected into the central inlet pipe and mixed with the raw water. The mixture is then evenly distributed into the air flotation tank via a moving distribution pipe. The movement speed of the distribution pipe is equal to but opposite in direction to the flow velocity of the effluent. This creates a "Zero Velocity" condition, minimizing disturbance to the influent. The suspension and settling of flocs occur under static conditions. Suspended solids float vertically to the water surface in this relatively quiescent environment. The flotation path is minimized and is unaffected by the effluent flow rate, allowing the flotation speed to reach or approach its theoretical maximum value.

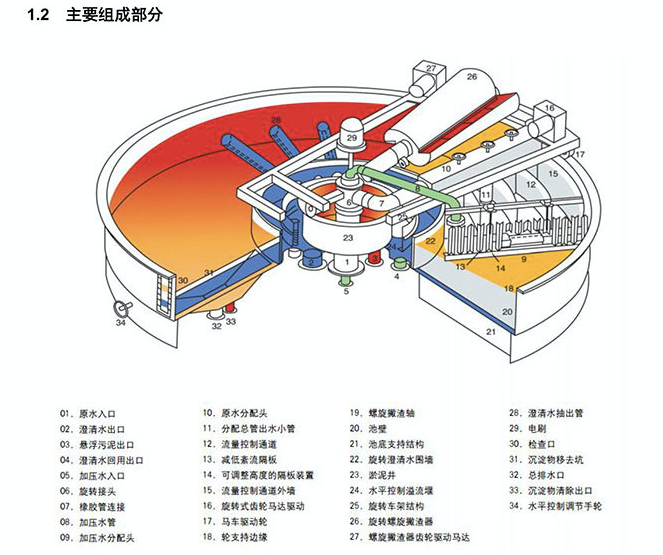

1.2 Main Components

(Section content not provided in original document)

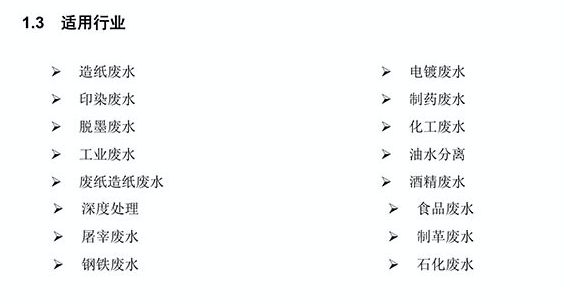

1.3 Applicable Industries

•Papermaking wastewater

•Printing and dyeing wastewater

•Deinking wastewater

•Industrial wastewater

•Recycled paper wastewater

•Advanced treatment

•Slaughterhouse wastewater

•Steel industry wastewater

•Electroplating wastewater

•Pharmaceutical wastewater

•Chemical wastewater

•Oil-water separation

•Alcohol production wastewater

•Food processing wastewater

•Tannery wastewater

•Petrochemical wastewater

2.2 Selection Parameters

Key parameters required for selection:

•Industry nature, Wastewater type

•Treatment capacity (m³/h)

•Material requirements

•Site requirements

2.3.1 Industry Nature

Shallow air flotation has a wide range of industrial applications. However, design parameters such as surface loading rate and retention time vary depending on the industry. The surface loading rate selection range is 6-8 m³/m²/h (for reference only), and the retention time selection range is 3-5 min (for reference only). Besides the equipment design parameters, the supporting chemicals (PAC and PAM) also significantly impact the treatment efficiency. Laboratory tests (jar tests) are required to determine the appropriate design parameter values and chemical dosage.

2.3.2 Treatment Capacity (m³/h)

The treatment capacity is generally determined based on the flow rate provided by the customer.

2.3.3 Material Requirements

Material selection for the shallow air flotation unit is primarily based on the nature of the wastewater. Common options include:

•Fully carbon steel construction with anti-corrosion coating.

•Tank body in carbon steel with anti-corrosion coating and stainless steel distribution mechanism.

•Fully stainless steel construction.

The specific material is decided based on customer requirements.

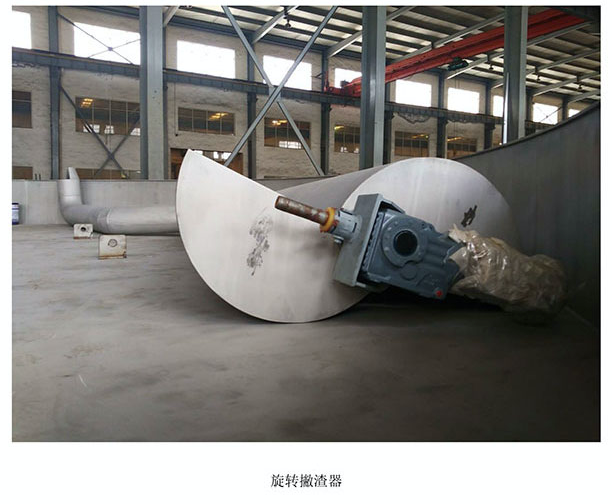

2.3.6 Equipment Photos